Mackay Bieker Moth

When speed matters.

When a group of top-level engineers, designers and builders come together with very few design restrictions, the meaning of fast is redefined. Meet the Mackay Bieker Moth.

"The V3 Bieker is a pretty big step up compared to the competition, both in terms of aerodynamics and system design. Mackay nailed all the important things with this design change.” Richard Didham

Click here >> Mackay Bieker Moth User Guide and Parts V4

Click here >> Mackay Bieker Foil Guide 2025

Find out more about the Mackay Bieker in the Features section below

BM-V3 Specifications

Length overall 3.355 m

Beam 2.250 m

Max. luff length 5.185 m

Max. mast length 6.250 m

Hull weight Unrestricted, general weight range 10-20kgs

Rigged Weight as little as 26kgs

Sail area 8.25m

Optimum skipper weight 60-80kgs

The Build

Producing complete consistency is our goal. Every part is checked, weighed and recorded so we have a complete build record for each boat.

Sailors can also apply their own expertise to develop their boats further.

Spare parts can be fitted easily and means that upgrade parts can be adapted to existing boats.

The Hull

Shape

A comparatively high-volume displacement shape, with a rocker profile provides an easy, low ride handling and un-sticky take-off characteristics.

The sleek hull shape (BM-V1) is designed to optimise aerodynamic flow (this is based on a recent 2023 flow analysis).

Material

An aircraft grade honeycomb is used to produce a significantly light weight yet stiff boat. The maximum stiffness to weight ratio has been achieved.

The laminate is a custom-made spread tow tri-axel pre-preg carbon fibre that reduces weight while adding torsional stiffness. High load points have been reinforced with unidirectional carbon fibre patching.

The mould

Built from a hi-temp carbon tooling prepreg, this mould helps to produce exceptional hull accuracy and consistency which means lighter hulls and precise alignment of all the components.

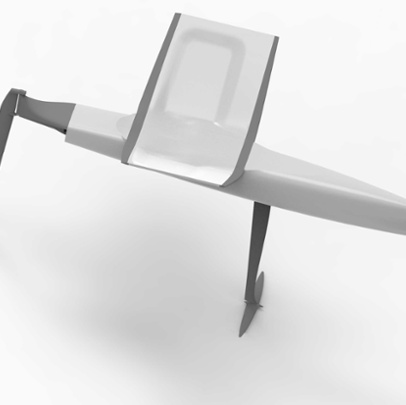

Wing Beams and Solid Wings

Using minimal surface area, the planform minimises aerodynamic drag while maximising heeling moment.

The wing is designed to let sailors impart kinetic energy into the boat during tacks and gybes.

Stiff single piece wing beams help maximise heal to windward.

The wing beams are high modulus pre-preg carbon, designed to eliminate the need for compression struts and unnecessary joins.

This rigid wing frame also reduces windage and streamlines the planform.

BM-V3 Wing Shape and Section Enhancements

• An adjustment to the wing angle which increases the righting moment when sailed at the optimum heel angle.

• Single one-piece beams used for ultimate strength and stiffness, with the fore and aft beam section shape refined to encourage attached flow.

The outer beam is now incorporated into the wing decks.

• A redesign of all connections between beams, wing decks and deck.

• A reduction of the planform areas.

• A slight reduction in weight.

The Deck

Designed with a deck-sweeping rig in mind, a forward deck fairing on the deck aft of the mast enables the sail to be sealed onto the deck.

BM-V3 Deck Interface Enhancement

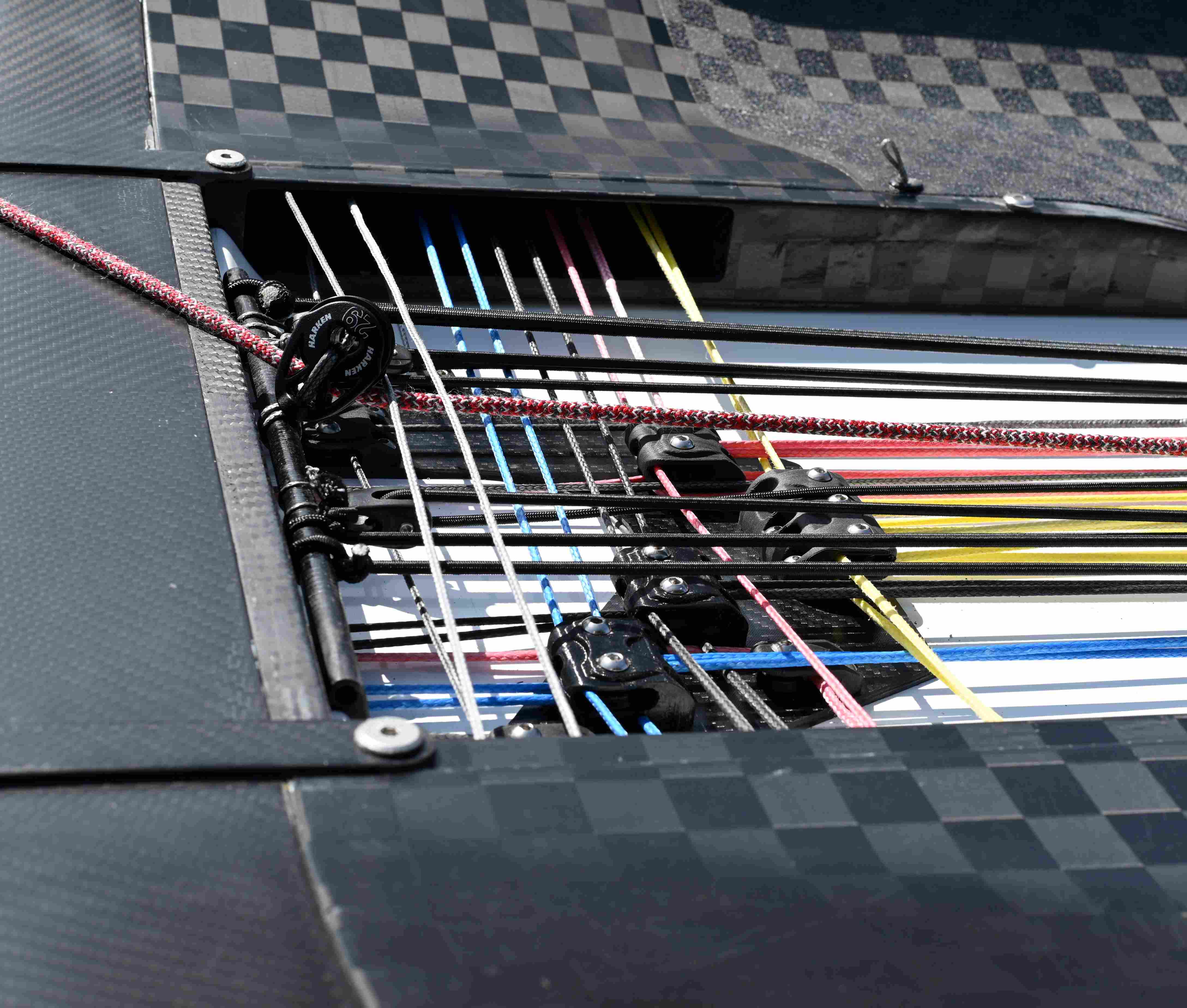

An incredibly clean wing and deck area enables easy maneuverability along with aero drag reduction. The new deck shape completely conceals the controls with the only rope visible is from the cleat plate to the outboard end of the tramp. Even the cleats themselves are mostly hidden.

BM–V3 Below Deck Enhancement

Space under the deck is used to house all the systems and controls. This removes drag created from the control lines on the wings and keeps the weight centralised. Now with a larger systems area, all systems move more efficiently which make for easier adjustments.

Gantry

The gantry’s defined lines and curves, combined with its 3-point attachment system ensures a lightweight that optimises airflow off the stern. As per the Class rule, the gantry is not watertight. It will hold water, including when the boat is at rest.

The low drag verticals have less area. They are shorter and also narrower in some areas. As a result they are also lighter.

Area and section shape. More area has more drag, but it also lifts the boat sooner in lighter winds. Section shape varies the amount of lift and drag. For heavier air foils the emphasis is more on reducing drag. On lighter air foils lift becomes more important, but not if it increases drag too much. It is always a compromise which is why development will always continue in the quest for more lift with less drag.

Solid wings have some handling advantages and aerodynamic advantages.

Soft wings are lighter.

For bigger sailors, the trade off is often in favour of having a lighter platform, whereas lighter sailors can take the aero gain of the solid wings.

To get the most aerodynamic gain, the deck faring should match or be a little longer than the foot length. Theoretically, longer is better, but it is also hard to sail with. It is no problem to cut down the length of a deck fairing to match your sail should you change at a later date.

The Hi-Top box is needed if you want your solid wings to fit into a box with your boat. Alternatively you can use the standard box and package the wings separately if you don’t travel a lot.

Air freight is charged by volume, so it costs less if you use the smaller box and pack the wings separately. However, this also has its risks, so we recommend the Hi-top box if you are regularly freighting your boat to reduce the chance of your wings being damaged or lost.