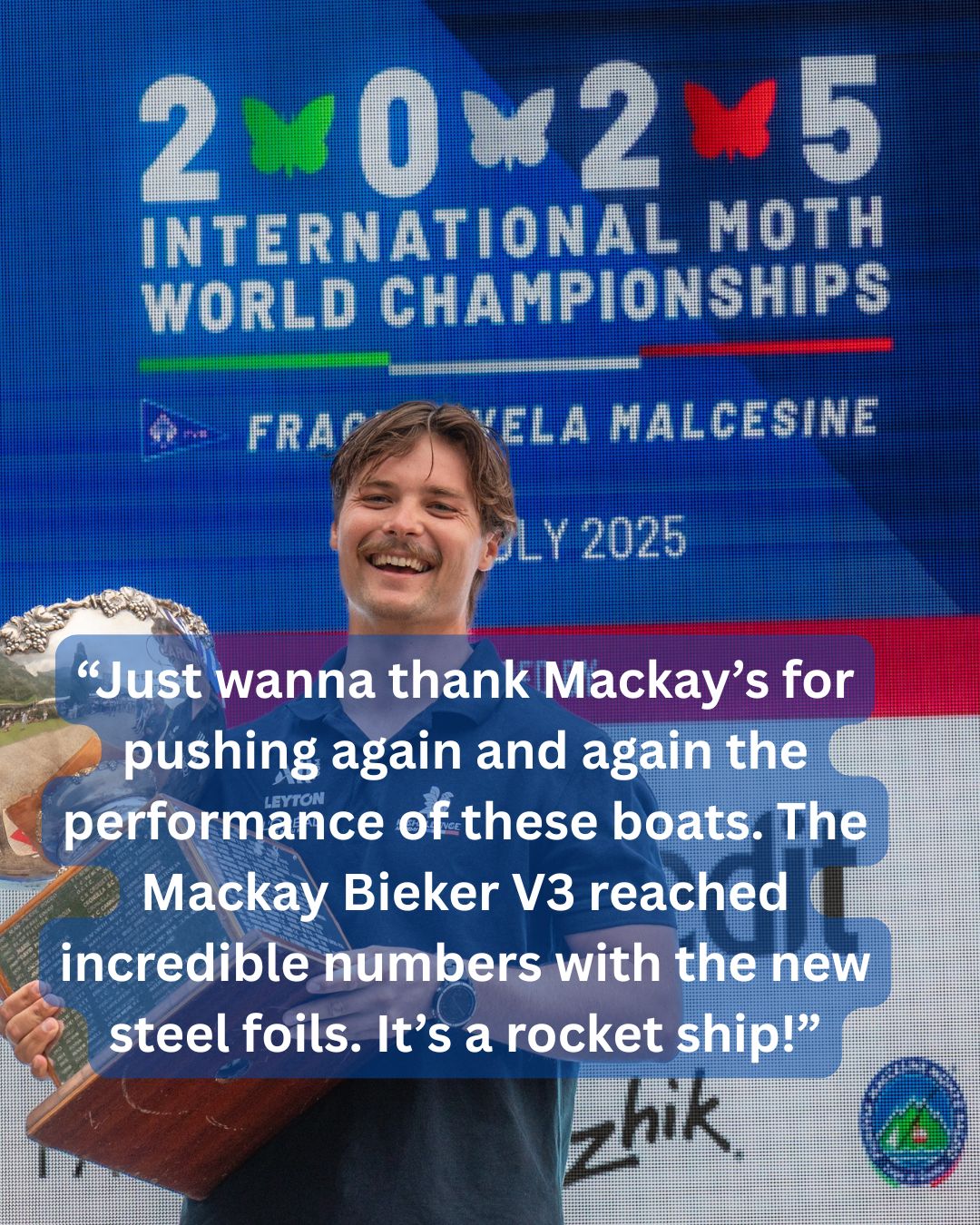

Our congratulations to Enzo Ballanger (FRA) on taking out the 2025 Moth World Championships. We also acknowledge, in hot pursuit, Tom Slingsby (AUS) and Jacob Pye (NZL), Victoria Schulthesis (MLT) 1st woman and Hattie Rogers (GBR) 2nd woman - all sailing a Mackay Bieker Moth.

With the 2025 Moth Worlds now concluded — where Mackay Bieker Moths dominated the fleet, claiming 9 of the top 10 spots and 17 of the top 20 — we take a closer look at the key performance upgrades made to the Mackay Bieker Moth over the past two years.

The BM-V3 Model

The Mackay Bieker Moth (BM-V3) was introduced following the 2023 World Championships.

This was based on a complete review of all areas of the very successful V2 design.

The design team, back in 2023, focused heavily on reducing drag on the platform, which included minimizing the wings' surface area, optimizing sectional shapes, and lowering friction drag through smarter system designs. We also refined the landing area for the sail foot to ensure a perfect seal between the sail and the deck. This required some big tooling changes by Mackay’s.

At the same time, throughout the year leading up to the 2024 worlds, nearly all control systems were refined and many were redesigned.

In all cases, tolerances in moving parts were reduced and refined, and materials were changed to create more precise and, where possible, simpler linkages in the systems.

Machine shops worldwide were evaluated to identify those capable of producing the most precise parts, and the internal layout was modified to create more direct paths to the lines, reducing friction. Aside from some sheaves, all parts are custom-made to achieve the best possible results.

For more information on the parts of the BM-V3 >https://mackayboats.com/index.cfm/boats/bieker-moth/

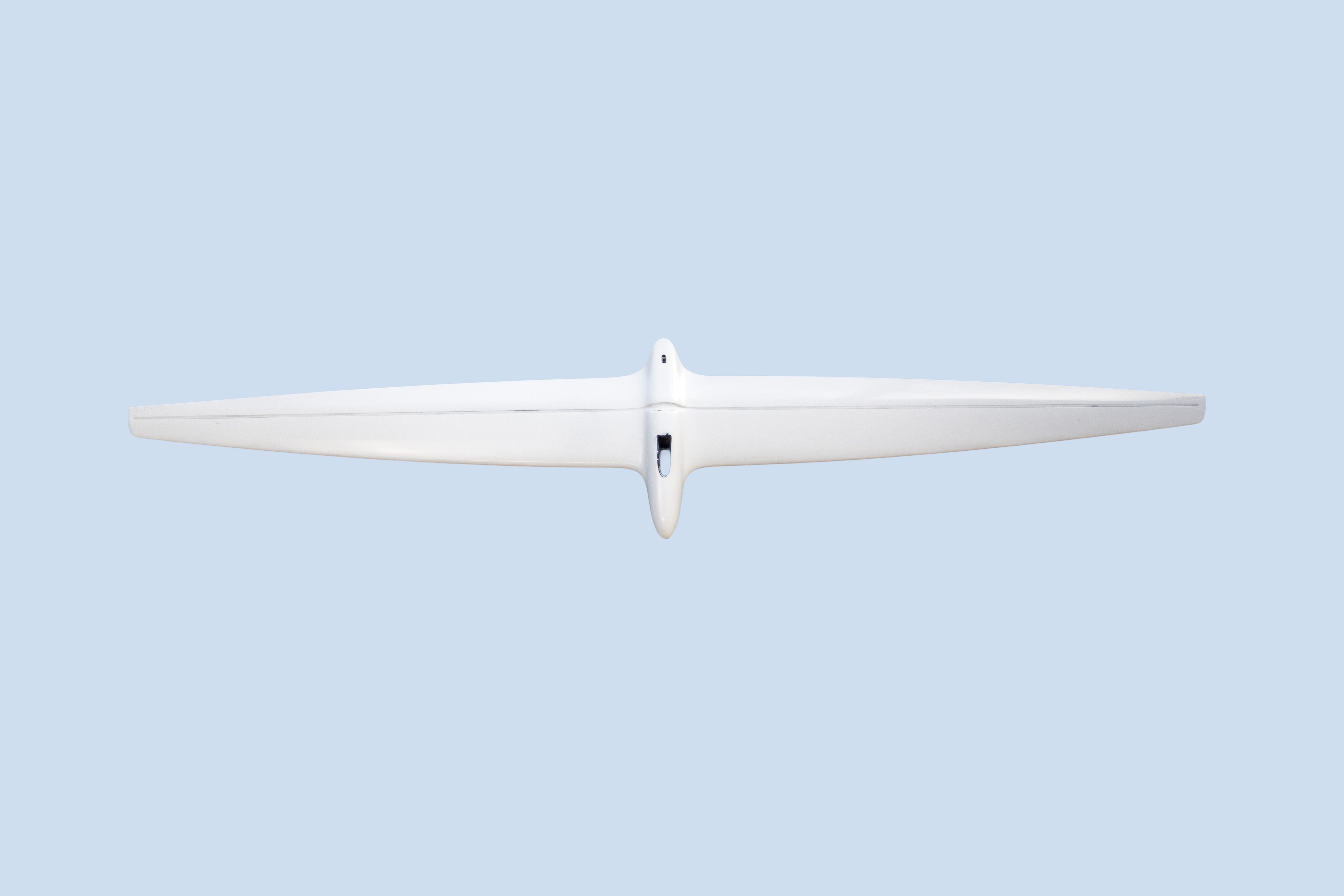

Foil Development BM-V3

Foil development continued up until the last minute before the 2024 worlds as we received increasingly better feedback from the many sailors who spent extensive hours on the water leading up to the regatta. This resulted in significant refinement of the foils, including the addition of steel in the lower half of the main verticals, which greatly reduced drag and increased speed.

As the speed increases, loads go up, and we quickly discovered other parts of the boats that approach their design limits and need to be re-engineered and refined.

The extreme conditions at the 2024 worlds caused sailors to sail for longer periods using high flap angles—something that hadn’t happened before. This prompted us to redevelop the flap systems on the main horizontal foils for the 2025 worlds. It involved extensive research and material testing to find a more robust solution for the flaps.

|

|

|

|

|

|

Production of the main horizontal 2025

After the Moth Class’s vote and rule confirmation on steel foils in March 2025, we also added steel to the rudder verticals for the 2025 worlds and introduced a refined Main vertical with a longer steel section.

|

|

Production of the Steel Rudder

Adding steel to the main verticals is always a trade-off; it can significantly reduce drag but adds extra weight. Once the boats are up and flying, the reduced drag is much more important, but at low wind speeds, weight becomes your enemy.

This trade-off has always limited the length of the steel section, but our steel foil design seems to strike the right balance in the trade-off to date.

Main Steel Vertical

To the Future

Many sailors are asking what the next developments will be.

We always try to design upgrades that can be easily retrofitted to existing boats. Foil development is a great way to accomplish this.

As a result of our successful foil program leading up to the 2024 worlds, we were asked to build the rudder horizontal foils for the Sail GP boats. Much of the manufacturing process is similar to what we use on the Moth, but of course, each time we face new designs, there are some new technology options that we can then implement on other boats we build.

Some of this technology, along with the debrief and feedback from the 2025 worlds, will give us ideas for new developments for the 2026 worlds..